Why did TOGO TOOL & DIE build a factory under the mountain?

TOGO Co., Ltd., a manufacturer of precision molds at precision +/- 0.001 (High-Precision Press Die, Tolerance +/- 0.001) for electronic and automotive components from the design process, production to after-sales service. The main factory is in Japan and another factory outside Japan by choosing Thailand as the location under the name TOGO TOOL & DIE Co., Ltd. in September 2013 at Sriracha District, Chonburi Province.

This plant is interesting in its way of thinking. TOGO TOOL & DIE's Managing Director Mr. Masakatsu Higashi reflects a profound but simple way of thinking. The work that will turn out well must come from a good foundation, so what are the elements of a good foundation? We'll talk about it in this exclusive interview.

Natural temperature results from the factory under the mountain

The idea of building a factory under a mountain was initiated from the TOGO factory in Japan. It was founded in 1985 by Mr. Naruo Higashi, currently the CEO and Mr. Masakatsu Higashi came up with the idea. At that time, they were inspired from "Rocket Base" and brought it to the top until it became an Underground structure special factory building, similar to the factory in Thailand.

The original idea was to dig a large deep hole in the soil to build a factory that could maintain a constant temperature of 23-24°C summer will be very hot while the winter is cold. This makes it more difficult to maintain a constant temperature throughout the year. Therefore, this special underground structure of the factory building allows to naturally achieve the optimum temperature for the production of high-precision molds.

But when exploring the construction guidelines and budget Found that the budget to build the factory is very high. So look for alternatives that can achieve the same results. This made me choose to bring the soil to fill the surrounding area of the factory to make it look like a mountain instead of digging large deep holes and reduce the budget by up to 75%

Underground structure special factory building consists of

- The ground floor is a production section with only one large door for the truck and one smaller door. The lower floor has no windows.

- Upstairs is the entrance to the office. And there is a staircase leading down to the ground floor by a glass door to prevent colder air flow.

- Concrete base, separated between the office floor and the production part, thickness 50 cm.

- The sides of the plant walls are covered with soil. Also known as a “soil wall”, the thickest part is 3 meters thick and cascades up into the shape of a mountain.

There are not many air conditioners in the ground floor. It is mainly installed in a room with many machines. To help eliminate heat from the continuous work of the machine for a long time. and also helps to extend the working life of the machine And save the electricity bill of air conditioners as well. In addition, air ducts are used to manage the flow of cold air to distribute to other parts, including corridors.

For the layout of the machine, it is important, near the door where it is more difficult to keep the temperature stable. It is a place to set up the machine for rough milling jobs that do not require much temperature control. Next, inside will set up a grinding machine (Grinding Machine), Wire-cut EDM Machine, and finish the production process at the quality measurement section.

Female engineers because women are determined and try

In work that requires high precision expertise and attention are very important. The expertise of the engineers at the factory in Thailand is not equal to that of the Japanese factory. Therefore, we are dedicated to training our personnel in terms of skills and technology as much as possible and organizing a project to send engineers to work at a factory in Japan to enhance the experience and knowledge of personnel. The factory in Thailand will focus on recruiting female engineers because women are determined and try to pay attention to the standard of the workpiece which is what we attach great importance to today. TOGO TOOL & DIE is able to produce molds with specifications equivalent to those in Japan. And at present, most of TOGO TOOL & DIE's professional engineers are female engineers.

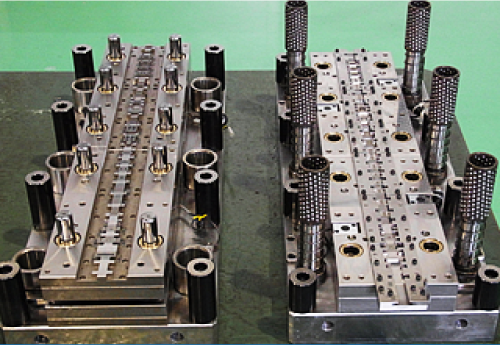

Good work must be built on good machines

With TOGO TOOL & DIE as a manufacturer of high precision molds at precision +/- 0.001 (High-Precision Press Die, Tolerance +/- 0.001) for electronic and automotive components. From the design, production process to after-sales service of the workpiece make use of A total of 6 high-precision wire-cut EDM machines from Sodick.

It is a wire-cut EDM machine with 2 oil milling machines, which are used in applications requiring a smooth, ultra-glossy surface, and 4 water milling machines.

Challenging, sincere, initiative with advanced technology

Currently, parts manufacturers in Thailand most of the molds are imported with high precision from abroad, which TOGO TOOL & DIE sees an opportunity to expand this part of its customer base to order in Thailand instead because it will get a cheaper price than imported from abroad and reduce the order time as well for the company's customer base, there are both in Thailand and abroad. This will cover Japan and countries in Southeast Asia, which will receive orders directly from the parent company in Japan, 30%, and take orders by themselves, the other 70%, in 2017, the total revenue is 50 million baht.

In terms of confidence, Mr. Higashi also stated that Thailand has a wide variety of parts manufacturing industries, both in terms of customers and workpieces making it more attractive to market opportunities. This will build on the continued growth of the precision parts market in Thailand.

For future investments of TOGO TOOL & DIE, it is possible to build more factories to expand the business line to the production of precision parts in the form of mass production for other industries that have higher technology. This is a challenge to support the work that the customer wants.

About TOGO Co., Ltd. Japan

TOGO Co., Ltd., a Japanese company Founded in October 1985 by Mr. Naruo Higashi who is currently the CEO of the main factory in Kakata City. Kagoshima Prefecture 1 Japan and another factory in Thailand. Its main overseas markets are Singapore, Thailand, Malaysia, the Philippines, China, Taiwan and Indonesia. The highlight of the factory TOGO Co., Ltd. is the specially designed underground structure. It has temperature stabilization properties. Resistant to external temperature changes. In addition, the structure that separates the foundation from the building (seismic base isolation) to withstand earthquakes. In addition, TOGO Co., Ltd. is also involved in the KSAT (Kagoshima Satellite) project, which was launched into space with the space probe “Akatsuki” by the H rocket-IIA No. 17 on May 21, 2010, by using the company's technology to reduce weight and strengthen the satellite structure. and has participated in the small rocket development project since fiscal year 2017.