Talk to Okamoto in METALEX 2019 to Discover How Further the Grinding Innovation Has Been

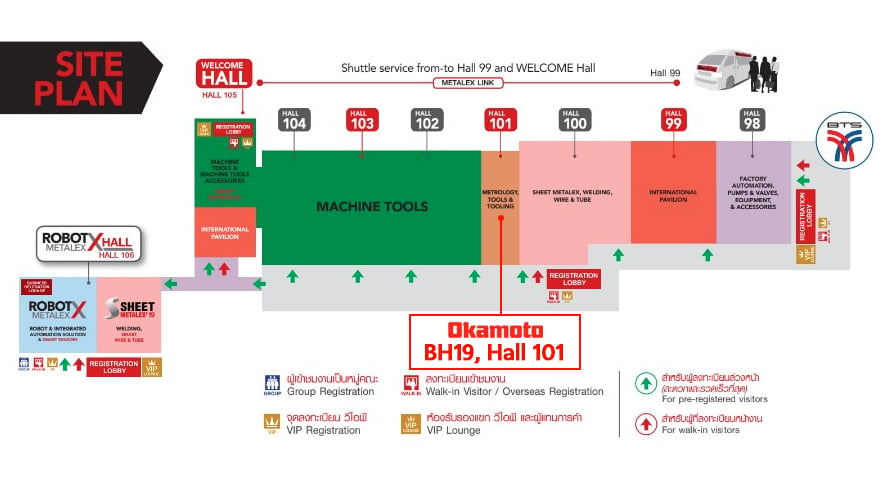

The demands for high precision parts are getting higher and higher in many industries, for example, the micro-precision for the precision parts, automotive, electronics, molding industries, aerospace and semiconductors industries. To catch up with the wave of changes in the industries, The METALEX 2019, which will be held on 20-23 November 2019 at BITEC Bangkok, is one of the events that showcase the technologies and innovations from Okamoto, the only total solution for abrasive process machine manufacturer in the world. Mr. Tetsuya Yamada the General Manager of Okamoto (Thai) Co., Ltd. told M Report about their interesting technology presented under the "Grinding Innovation" theme that it will serve Thailand and ASEAN markets as well as the needs for future technology that the company has been committed to developing continuously to the goal that has not been achieved, which is the ultimate flat surface. Those who are interested can visit Okamoto at booth BH19 Hall 101.

Okamoto Presents “Grinding Innovation” at METALEX 2019

As Okamoto’s highlight of this year’s METALEX, the grinding machine is developed under its main “Grinding Innovation” theme, which covers the line-up products available worldwide. This theme represents the need to upgrade the grinding work as in the sentence “Renovate Grinding Common Sense.”

“Grinding Innovation” theme consists of the following four items:

- High Efficiency: Higher rigidity machine combined with super-sharp grinding wheel, Effective Coolant Fluid, and additional options to increase the grinding efficiency.

- Universal: External, Internal and face grinding by one machine.

- Measuring on the Machine: measuring work on the machine after the grinding makes the process even more convenient.

- Full Automation: Automatic Surface Grinding System as Future’s Grinder, no human labor is needed.

The “MAX-N-OD Series” CNC Ultra High Precision Cylindrical Grinding Machine is one of the highlighted machines that are used to manufacture precision parts and is very popular among Thai clients, especially those in the precision parts industry. They are used to manufacture as important parts of a car (after wording is deleted). They are also suitable to be used in manufacturing machine parts as well as in food industry. The MAX-N-OD Series are used to manufacture the mold for bottles, cans and precision tools.

The “ACC-CAiQ Series” NC Precision Surface Grinding Machine is New Column movement surface grinding machine which Okamoto would like to recommend upgrade of existing surface grinders.

Both machines are equipped with touch-screen monitor designed to be easy to use. Using icons instead of words and the built-in software are user-friendly, and can solve the labor shortage problem especially highly-skilled workers, which has been a continuously more severe problem.

Besides the touch-screen monitor, both machines have options with a Fine Bubble making unit “GRIND-BIX” and “GRIND-X NORTON” grinding wheel, as part of Grinding Innovation theme.

Ultimate Flat Surface: Set an Impossible Goal for Perfectly Flatness Workpiece.

"The goal of Okamoto is the Ultimate Flat Surface or Zero Flat for producing completely flat surfaces. In reality, it would certainly be impossible. However, we aim to develop our grinding machine to produce better work than micro, smaller than nano, and we will continue to achieve this goal to make the workpiece surface flatness and as close to the perfectly flatness and quality as possible. In other words, we aim for the impossible result in order to further improve our customer's work surface, which will meet the demand for IT technology, nano-technology, semiconductors, and other technologies in the future. "

After-Sales Service is Important

Mr. Tetsuya Yamada says that Okamoto has three production plants: in Japan, Thailand and Singapore. The one in Japan is responsible for designing all the machines and the production of high-precision grinding machines. The Thai plant is in charge of the production of medium-size surface grinding machines while the Singapore plant is in charge of the production of CNC cylindrical grinding machines, CNC internal grinding machines, Rotary surface grinding machines, and bigger–size surface grinding machines.

"Every Okamoto factory can supply parts and machines for one another. Under the same quality control standards and production system in all three factories, the company can ensure our clients that the support and after-sales service will be fast and absolutely effective. Our factory in Thailand also helps us to support Thai and ASEAN customers directly and quickly as well."

, more than 2,000 Okamoto machines are being used in Thailand and there are more than 20,000 customers around the world. The Thai factory exports 110 surface grinding machines a month to countries around the world.

Mr. Tetsuya Yamada commented that the demand for precision parts for electric cars (EV) and Industry 4.0 will be higher in the future. Thailand is no exception. Therefore, those who are interested in these markets can stop by Okamoto booth to get some advice on appropriate machines, as well as those who want to upgrade their machines to automated system in this IoT days or to replace the harder-to-find skilled workers.

For those who are interested, please visit Okamoto at booth no. BH19, Hall 101, METALEX 2019 from 20-23 November 2019.