NEODO S90° Line - A New Way to Increase Profitability in Rough, Semi-Finish, Square Shoulder and Face Milling Operations

NEODO S90° Line - A New Way to Increase Profitability in Rough, Semi-Finish, Square Shoulder and Face Milling Operations

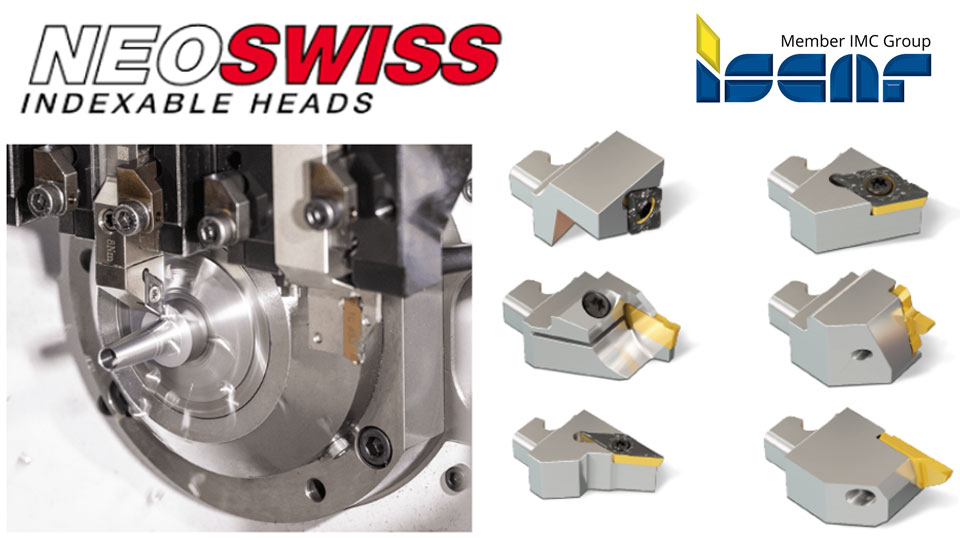

ISCAR introduces new indexable milling cutters for 90° square shoulder and face milling applications which mount square inserts with 8 cutting edges.

This new family of tools was designed for rough and semi-finishing operations, intended for highly efficient face milling applications, primarily for steel and cast-iron.

The new HELIDO S890 FSZ …R08 face mills feature a 90° cutting edge angle and mount square double-sided inserts (S890 SZMU 08) with 8 cutting edges. The new cutters have a face mill design configuration and are available in a diameter range of 40-125 mm.

The advanced design combines a strong insert structure, a durable cutter body, secure mounting, and advanced carbide grades. This innovative solution enables face and square shoulder milling, while providing an additional option for milling close to shoulders where there are workpiece or work holding fixture constraints.

S890 SZMU 08… insert features:

- Square double-sided pressed-to-size inserts

- 8 helical right-hand cutting edges for machining at depths of cut (D.O.C.) up to 5 mm

- Specially shaped rake face insert which ensures a positive rake and low cutting forces

- Strong and durable insert structure

- Wide wiper flat for improving surface finish

- An effective and economical solution for face and square shoulder milling. The inserts are produced from superior SUMO-TEC carbide grades, which provide excellent performance and longer tool life.

S890 FSZ…R08 milling cutter features:

- 90° cutting edge angle

- Maximum 5 mm depth of cut (D.O.C.)

- Extremely rigid screw clamped inserts due to the dovetail profile of the insert pocket

- Advanced cutting geometry which reduces cutting forces and assures smooth cutting and low power consumption

- Coarse and fine pitch configurations of the cutters

- Higher tooth density for improved productivity

- Coolant holes (up to 125 mm Dia. cutters), directed to each cutting edge for efficient cooling and chip evacuation

- A highly economical solution which provides an optimal price per cutting edge

- Excellent performance for diverse machining conditions and interrupted cuts

The new family offers technical advantages combined with a very attractive price per cutting edge. HELIDO S890 FSZ …R08 cutters provide highly productivity solutions for face milling.

Iscar (Thailand) Ltd. policy is concentration in sales and service product for support metalworking full line for all industry such as automotive, die and mold, Electronics, aerospace and any mass production. Company's policy have a good wishes our client success in quality goods production, short lead time in process and save cost effective also. Their product that produce from our affiliate were certified product by ISO 9001 and QS-9000, that we guarantee quality all of product perfectly. We provide service and technical team for solve problem in manufacturing process in order that short process and highest effective and also turnkey cost reduction consultant.

More Information, please contact:

Mr.Jarupong Worahan

Iscar (Thailand) Ltd.

Tel. 02-7136633-8, Fax 02-7136632, 02-7120836

Email: [email protected]; [email protected]

Website: www.iscarthailand.com

.jpg)