ZEISS Smartzoom 5 Automated Digital Microscope

ZEISS Smartzoom 5 Automated Digital Microscope

Industrial microscopy from ZEISS stands for superior optical quality and top performance. And for intelligence you can put to work.

Smartzoom 5, the smart digital microscope that’s ideal for quality assurance applications in virtually every field of industry. Quick and easy to set up, fully automated, and equipped with dedicated quality assurance and quality control components.

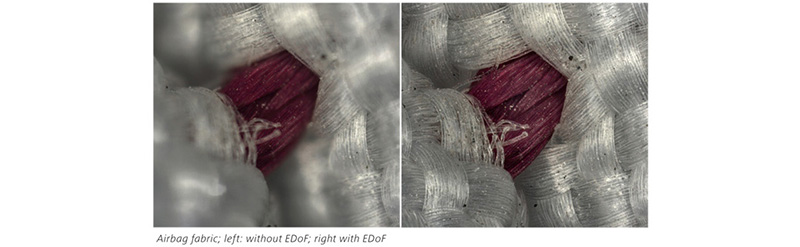

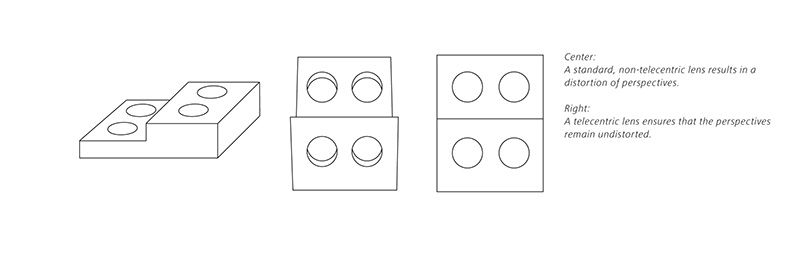

Enhanced Depth of Field (EDoF): Depth of field is inherently limited in light microscopy. Smartzoom 5 overcomes this with the ability to acquire a series of images at different focus settings, then processing and reconstructing a final extended depth of field or 3D image. Telecentric objectives ensure that these images are free from distortion in the third dimension, providing a clear view for inspection and documentation of 3D surfaces or surface profiles.

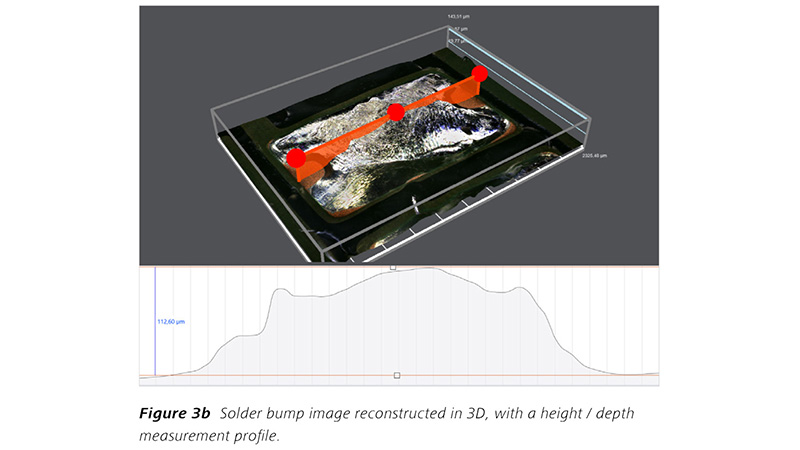

Image reconstructed in 3D: Smart Zoom 5. A further attribute of light microscopy imaging is its ability to measure contour, form or surface dimensions as 3D topographical and cross sectional image data, also shown in Figure 3b.

Telecentric optics assure distortion-free 3D images: Repeatable acquisition of 3D images, with exact placement of measurements in a surface profile, requires telecentric objectives. This means that images will scale correctly in the Z-direction due to the parallel and vertical beam paths produced by a telecentric objective. On Smartzoom, this means 3D images will be free of distortions in the third dimension and measurement excursions that can occur due to slightly different focus settings will be minimized.

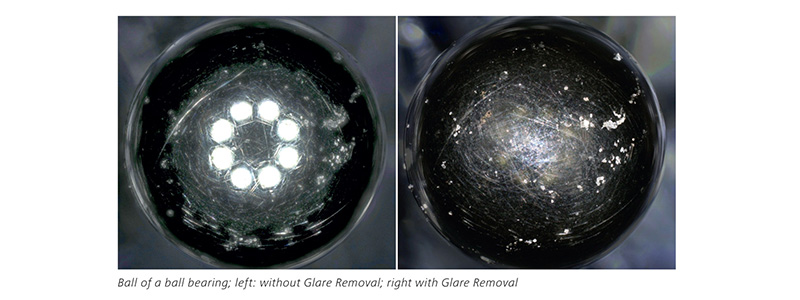

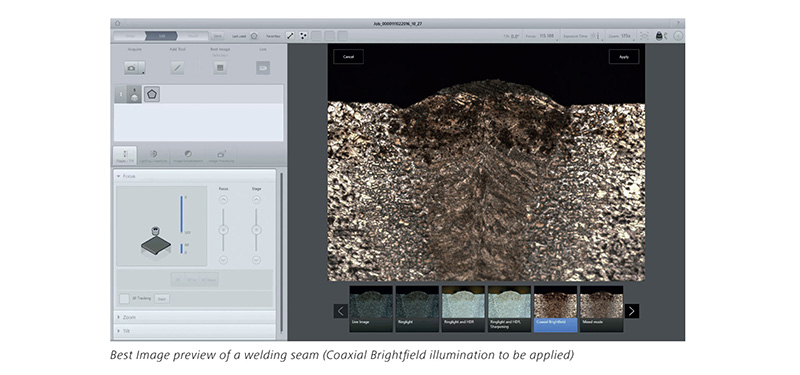

Smart Illumination: Another challenge for light microscopy is the suppression of reflections from highly reflective surfaces. Smartzoom 5 features segmented LED ring light and coaxial lighting for all objectives – plus smart software features such as Best Image and Glare Removal – all to assist the operator in choosing, and repeating, the best possible illumination conditions.

Best Image Preview: The Best Image functionality generates image previews showing different illumination settings: segmented ring light, coaxial light, and a mix of segmented ring and coaxial light— with or without HDR and image sharpness enhancement. Select the image that best reveals the attributes of the subject part—it’s that easy. Even better, simply recall the exact same preferred lighting settings for inspection and documentation of the next part in the batch, or when you are the next operator in the line.

Job Mode: A typical quality inspection workflow is likely to include images or measurement data from different locations on the part, with the same magnification and lighting conditions applied to multiple similar parts in a production batch. The sequence of acquisition parameters, together with the instrument settings at each acquisition, can be saved as a “job” by the laboratory manager, system supervisor or an experienced user. This makes it easy for less experienced operators to retrieve and execute the predefined inspection workflow, without worry about relocating the exact same regions of interest, focus or illumination settings. Job Mode gives you further assurance that any quality observation anomalies are real, instead of being caused by operator error, the differences between operator experience levels, or even unique lab protocols.

Tilting angle: microscope’s swing arm you can view structures on the sample surface from continuously adjustable angles. As you do so, the pivot point of the swivel axis remains stable, and likewise the focus remains squarely on your sample.

More information, please contact:

Factory Max Co., Ltd.

Tel: 02 759 9100

www.factorymax.co.th

Line: @Factorymax