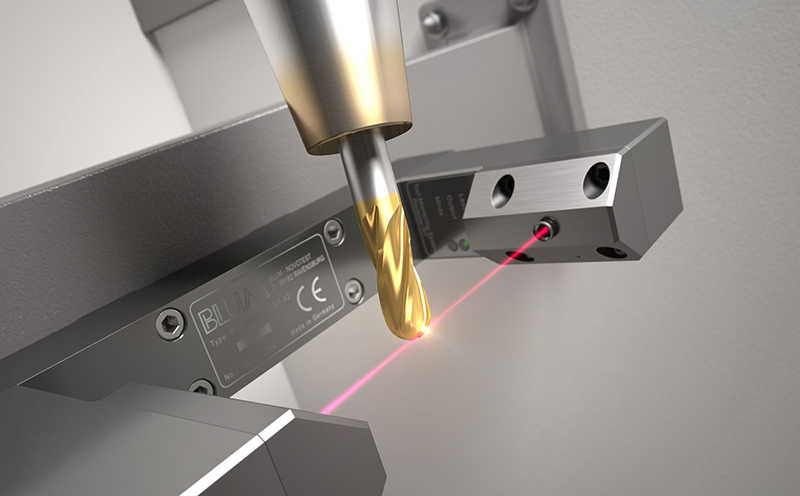

Blum LaserControl Micro Compact NT | Non-contact tool setting system for machine tools

High precision l reliable l The world’s number 1st

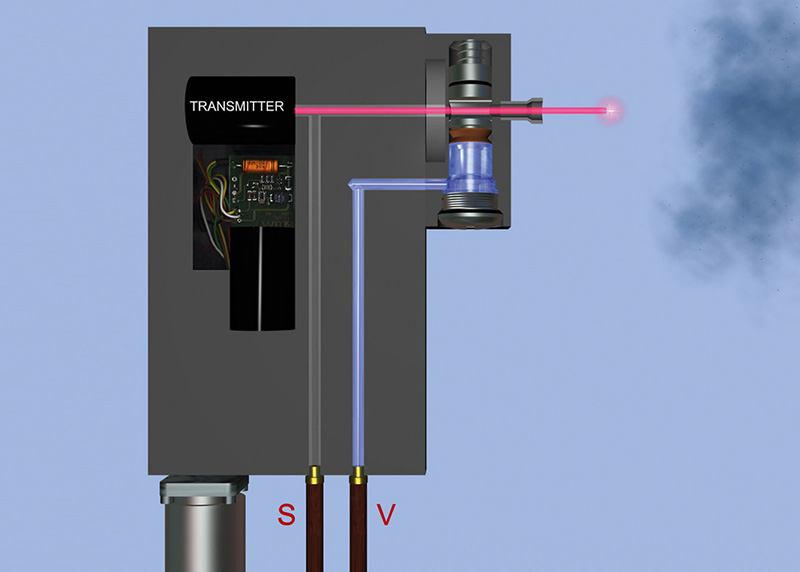

Laser measuring system for CNC machining centres for non-contact tool measurement and tool monitoring under the harshest conditions. Unbeatable precision and reliability due to high-quality laser optic, intelligent NT Electronics and unique

BLUM protection system.

- Tool Breakage Detection

Non-contact breakage detection of centric tools such as drills, mills, engraving tools, taps and reamers.

- Tool Length Measurement

Non-contact tool setting in length and radius at nominal speed including compensation of dynamic spindle drift at high rotational speeds.

- Tool Radius Measurement

Recording of form error on tools with circular cutting edge geometry. Data basis for 3D tool radius compensation “3D-ToolComp” by Heidenhain.

- Tool Form Measurement

Setting and monitoring of length, radius and cutting edge radius on tools with circular cutting edge geometry.

- Tool Form Monitoring

Monitoring for cracks or wear by scanning the tool cutting edges.

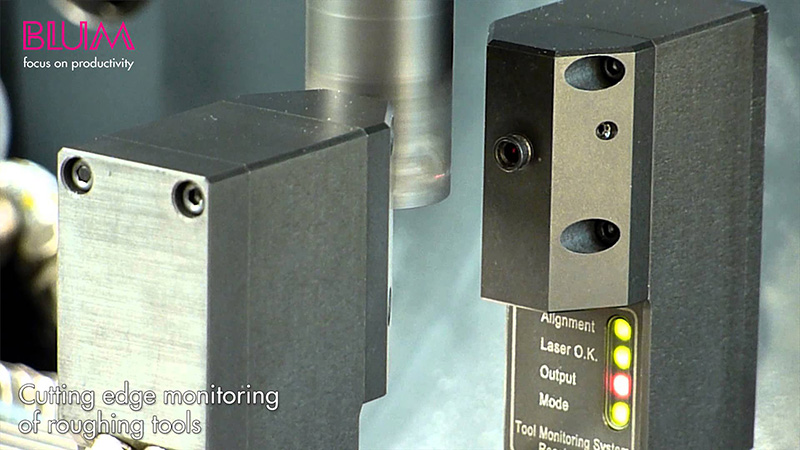

- Single Cutting Edge Monitoring

Monitoring of tools regarding cutting edge breakage and missing tool inserts.

- RunoutControl

Rapid run-out monitoring in less than 1 second for highly productive machining centres.

- GrindControl

Dynamic measurement of grinding tools and grinding wheels by laser measuring system.

- MicroWearControl

Fast monitoring of tool cutting edges for microbursts in a highly productive environment.

Extremely precise support system

Extremely precise support system for tool setting and monitoring under harshest conditions

- Tool setting at nominal spindle speed

- Highest absolute accuracy due to focused laser beam

- 100 % process reliability due to patented NT-Electronics

- Blum pneumatic unit and shutter system provide superior protection

- Pre-aligned laser for easy mounting

- Programmable by integrated microprocessor

Key benefits:

- Increased productivity and production quality

- No subsequent damage due to tool breakage

- Reduced set-up time and unmanned operation

- Reduced scrap rate

More information, please contact:

factorymax.co.th

Tel. 02 759 9100

www.factorymax.co.th

Line: @Factorymax